Our company operations extend to the waste management of products related to the heavy, machinery, automotive, electronics industry.

Handling small electronic appliances

Among the wide variety of electronic products, the processing of small domestic electronic appliances is an important area. From microwave ovens to electric razors, this category contains a wide range of devices.

We grind these with chain crushing equipment, then apply manual and machine separation technologies to separate valuable materials. After opening, we clean the materials, removing all contaminations, then collect them into units of cargo to rationalize storage and transfer. Two complex machinery lines are available to perform this task, with a production capacity of 9-10,000 tonnes/year.

Handling visual display appliances

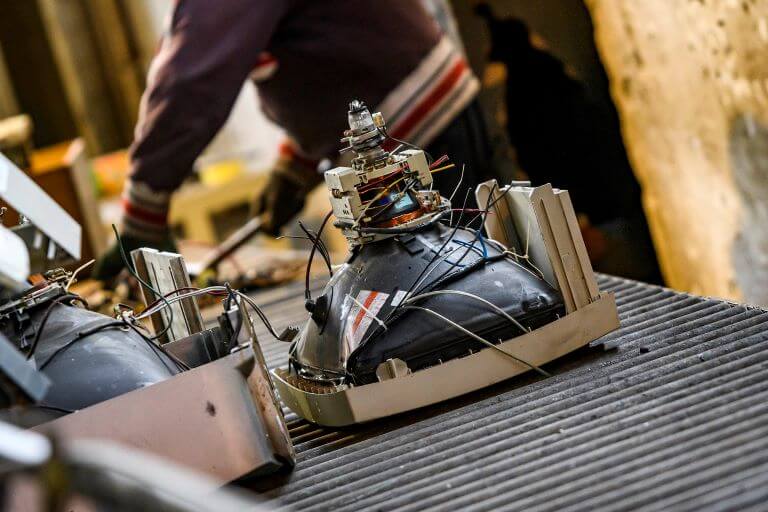

In recent years, the change in this sector was all but revolutionary. Previously, in industrial and residential practice, we encountered big cathode ray visual display devices (CRT TVs and computer monitors). Today, due to recent technological advancements, flat screen display devices became available commercially, first with LCD and plasma, or more recently LED, OLED technologies. Accordingly, our plant contains two processing machinery lines: one for CRT devices, the other for LCD devices.

The disassembling of CRT devices is done on an inversed assembly production line. The next step is to process the picture tubes extracted from the device, separating the glass and metal the tubes contain. Naturally, we also ensure the disposal and collection of materials classified as hazardous. The capacity of the processing equipment reaches 6,140 tonnes per year.

The processing of waste LCD/LED/OLED devices is performed on a machinery line specifically designed by us. As a first step, we use a special shredder to access the materials making up the device. Separating the plastic components is an important step. In this phase, we first classify them by size, then the already prepared plastic-based particles undergo further separation.

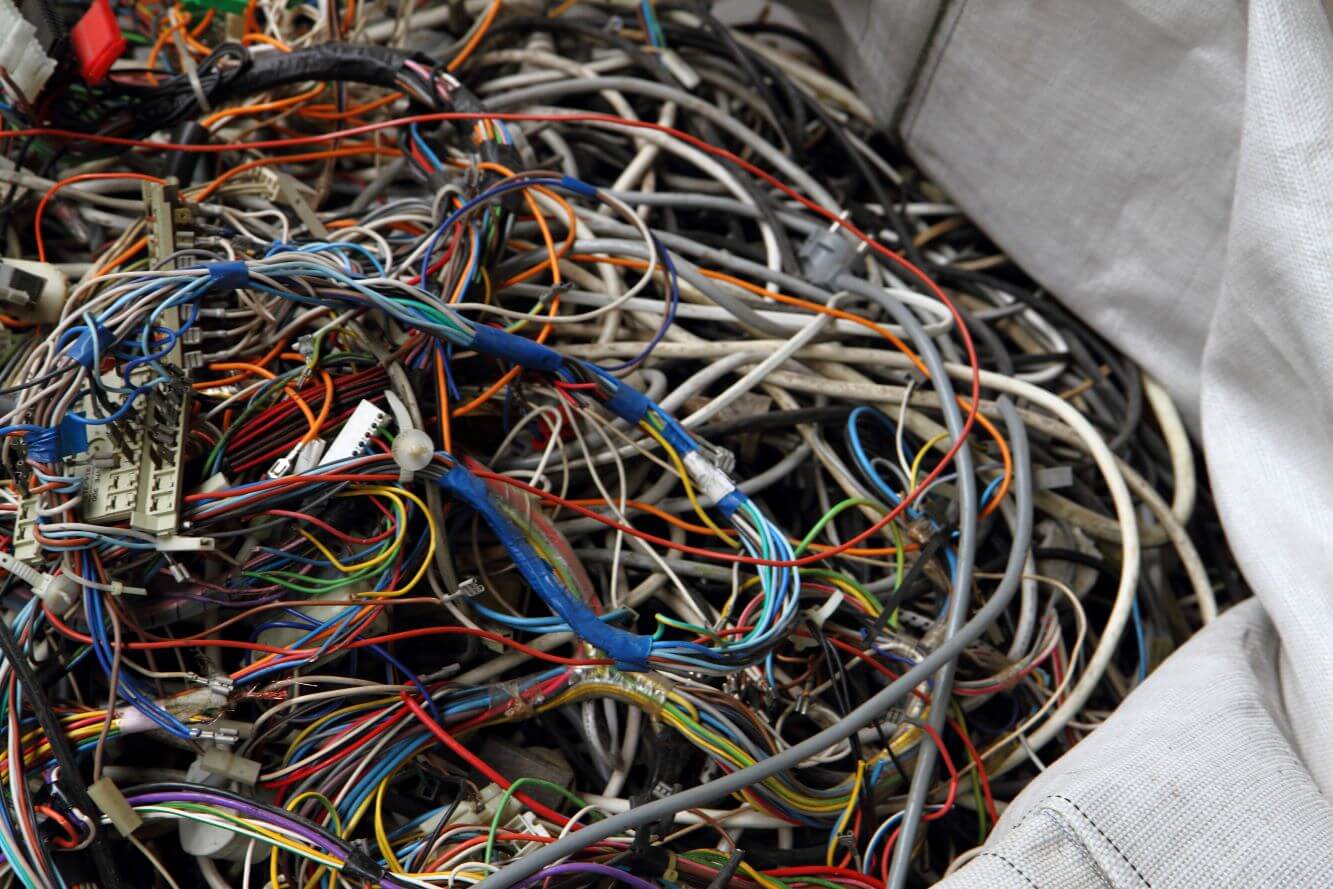

Recovering cables and wires

The professional separation of electrical conductors is important, since processing 40-100 mm diameter transmission cables requires a completely different technology compared to thin wires like multiconductors.

During waste processing, we first categorize cables by size, then cut them into smaller pieces. The cables, which are already of a workable consistency, are then fed into a so-called core-splitting machine, where the metals and insulating materials are separated in one or more steps. The end product produced by the technology line is peak quality, high purity granulated aluminum, copper and plastic. The capacity of the equipment line is 2,000 tonnes/year.

Handling industrial amortization waste

With our comprehensive service, we provide onsite disassembly of technological equipment, metal structures and machines that have grown obsolete within industrial company premises.

Recovering aluminum and copper-based waste

Copper or aluminum waste, pre-crushed and coarse-ground, is processed through a two-step grinding and separating equipment. Applying special processing and separating techniques, the machine produces 1 mm diameter, min. 99% degree of purity copper and aluminum scrap, depending on the input material.

Collecting and transferring battery waste

Our company is primarily active in the market with collecting lead-acid batteries, and this is the activity we are mainly equipped for with the necessary technical equipment. Our main goal is to supply the domestic lead smelter, but we continue to transport any surplus material to reliable international partners. The collection system contains hundreds of special plastic containers specifically certified for this purpose.